You need high-precision sensors to measure the movement of your machine, but your budget is limited. In this world of doing more with less, MEMS sensors can be the solution for plenty of industrial projects, not just cell phones.

1. Great Solution for a Limited Budget

MEMS sensors are a lower-cost solution as opposed to traditional, higher precision sensors. For applications that require high volume and lower precision, such as construction machines, MEMS sensors will fit in just fine.

2. Dynamic & Precise Performance

MEMS sensors offer a wider range (±90º, ±40G) and dynamic response up to 400Hz, which is useful for some vibration measurement.

With a resolution up to 0.0005º, some MEMS sensors are catching up to traditional, higher precision sensors. The 850 Tuff Tilt is a field-ready tiltmeter that uses low-cost MEMS technology, but with the precision to measure small geotechnical movements such as a bridge or a tunnel. The JMA-165 is a CENELEC/AREMA-certified, economical alternative for rail transportation measurement. It has the precision to control the motion of metro trains and test the speed of commercial passenger trains.

Some models are becoming more robust. The JDI-100/200 digital MEMS inclinometer offers full temperature compensation across all measuring ranges which enables it to perform to 0.005° accuracy.

3. The Limitations of MEMS Technology

You’ll free up some space in your budget but may have to make a sacrifice too. MEMS sensors generally have a larger drift over temperature which can be a concern for those who don’t have temperature compensation or heating capabilities. Relative to other traditional sensor technology, MEMS sensors typically have lower precision. If you don’t need to measure something in increments of micro radians or micro g’s, MEMS will suffice.

What They’re Used For

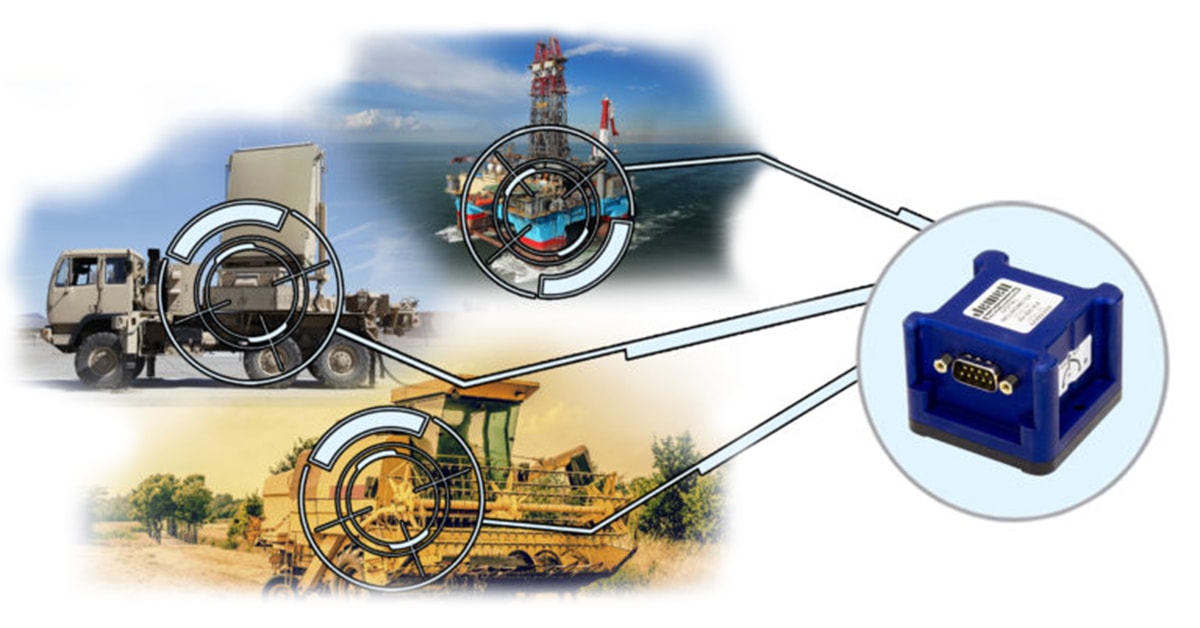

MEMS sensors have matured to serve not just cell phones anymore. The industrial market, including construction and agricultural OEMs, can implement a MEMS-based sensor into their machinery. The sensor can measure and control the positioning of the machine’s tools for optimum performance. They can also be used for platform leveling for mobile cranes and radar as well as testing in the laboratory or classroom. If you’re still looking for a tilt or motion solution for your project, talk to a sensor expert.