MEMS sensors have been a booming segment of inertial solutions for a number of applications, not just cell phones anymore. Market revenue in the industrial sector is expected to rise from $16 million in 2013 to $120 million by 2018 according to studies done by IHS. The crystal ball into the future of sensors is clearly showing MEMS.

So why MEMS for industrial projects when many other sensing technologies have been suitable in the past? MEMS brings some unique advantages to the worksite.

1. MEMS Have Matured

MEMS accelerometers have been produced in high volume for 25 years, why are they just now showing up in industrial control applications? The early MEMS parts had issues with drift, noise, repeatability, etc. Don’t worry about that airbag you relied on back then, the impact associated with a crash is easy to measure, so those old parts worked just fine there. Today’s MEMS have come a long way towards meeting the quality and precision of our classic Force Balanced sensors offering a great compromise between price and precision.

2. The Precision is Just Right

For industrial applications, this low-cost alternative is an asset. The resolution of MEMS models does not quite compare to that of a Forced Balance or Electrolytic sensor, but for many applications, that’s okay. For OEM applications such as cranes or combiners, you won’t need the accuracy of a sensor that has the precision for leveling a railroad or monitoring sediment (although some MEMS models can reach a resolution of up to 0.0005º). The option of MEMS offers the precision necessary for these industrial projects without taking a hefty bite out of the budget.

3. Relatively High Bandwidth for Vibration Measurement

It’s no question that MEMS can be used for plenty of OEM applications such as construction equipment, agricultural machinery, or platform leveling, but they can be used for testing applications too. With a bandwidth up to 400 Hz, users have found MEMS accelerometers to be useful for vibration sensing conditions such as automotive testing or monitoring the pitch and roll of an aircraft. The vibration and durability of MEMS sensors are what we will dive into further for the next post.

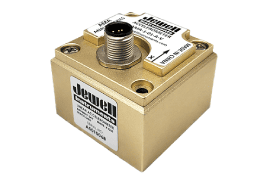

If an industrial or vibration measurement application is what you’re trying to solve, a MEMS inclinometer or accelerometer could be your answer. Talk to us to learn how each sensor can be customized for your application.